Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

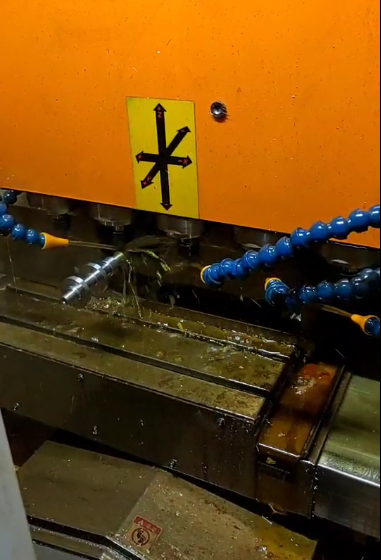

Special Metal Invar36 is a low-expansion iron-nickel alloy with a Curie point of about 230°C. Below this temperature, the alloy is ferromagnetic and has a very low coefficient of expansion. Above this temperature, the alloy is non-magnetic. , the expansion coefficient increases. Invar36 alloy is mainly used to manufacture components with approximately constant dimensions in the range of temperature changes, and is widely used in the radio industry, precision instruments, appearance and other industries. After long-term use in the aviation factory, the function is stable; the heat treatment process and CNC Machining technology should be strictly controlled during use to ensure the stability of the material.

Chemical composition of Invar36:

| Ni | Cr | Fe | C | Mn | Si | Co | P | S |

| 35-37 | ≤0.2 | margin | ≤0.03 | 0.3-0.6 | ≤0.2 | ≤0.5 | ≤0.02 | ≤0.01 |

Density Invar36 : ρ=8.1g/cm

Special Metal Invar36 alloy cannot be hardened by heat treatment. For high-precision parts after cold working or CNC machining, when high temperature treatment is not suitable, we recommend the following stress relief and stabilization treatment: heating the workpiece to 315 ~ 370 ℃, 1 ~ 4h.However, it can be pickled with 25% hydrochloric acid solution at a temperature of 70 °C to remove the oxide scale. Under the pressure of 4000A/m, the residual magnetic induction intensity Br=0.6T, and the coercive force Hc=48A/m[1,2].

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.