Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

The Gravity Casting Parts easy to thermal cracking and cold cracking. SCZY analysis for you.

1. Thermal cracking

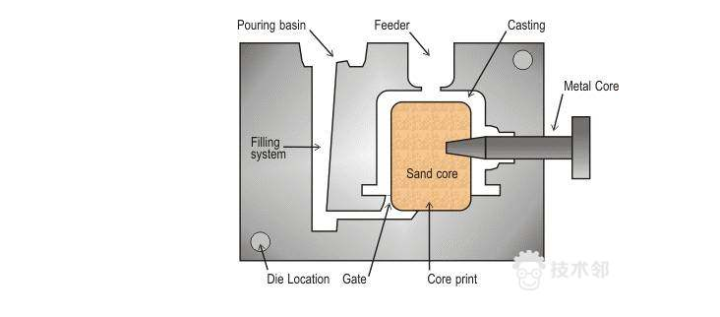

It is generally formed at the end of solidification when the metal is at a high temperature near the solid phase line. Its shape is characterized by short cracks, wide gaps, zigzag shape, oxidation colour in the seam. The casting parts is unreasonable, the alloy shrinkage is large, the shape (core) of the sand concession is poor and the gravity casting process is unreasonable, etc. can trigger thermal cracking. Sulphur and phosphorus in steel and iron reduce the toughness of steel and iron, making the tendency to thermal cracking increase.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.