Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Casting Iron is a general term for alloys mainly composed of iron, carbon and silicon. In these alloys, the carbon content exceeds that which can be retained in austenitic solid solution at the eutectic temperature.Process and method of casting Iron welding repair.

The welding method used for casting iron repair welding, the repair welding method is mainly based on the requirements after butt welding (such as the strength, color, compactness of the weld, whether to perform machining after welding, etc.), the structure of the casting (size, wall thickness, complexity, etc.) degree, stiffness, etc.) and defect conditions. Manual arc welding and gas welding are the most commonly used methods for repairing cast iron.

Casting Iron electrodes used for manual arc welding repair welding. When repair welding requirements are not high, ordinary low carbon steel electrodes such as J422 can also be used.

The methods of manual arc welding repair welding are:

(1) Preheat the weldment to a certain temperature (above 400°C) before thermal welding and semi-thermal welding, use a homogeneous electrode, select high current for continuous repair welding, and slow cooling after welding. It is characterized by good welding quality, low productivity, high cost and poor labor conditions.

(2) Non-cast iron electrodes are used for cold welding, which is not preheated before welding. Small current and dispersed welding are used during welding to reduce the stress of the weldment. The strength and color of the weld are different from the base metal, and the processing performance is poor, but the deformation after welding is small, the labor conditions are good, and the cost is low.

(3) Cold welding of polymer materials can also be used. This kind of repair only needs to clean the surface to be repaired and operate directly by hand.

(4) How to use cold welding materials: First of all, the surface to be repaired should be treated well. There must be no rust and oil, otherwise the adhesive layer will fall off. It is best to roughen it, which can increase the bonding between molecules. It can greatly enhance the service life of the repaired product. Also remember to choose a special cold welding material that corresponds to the material of the casting itself.

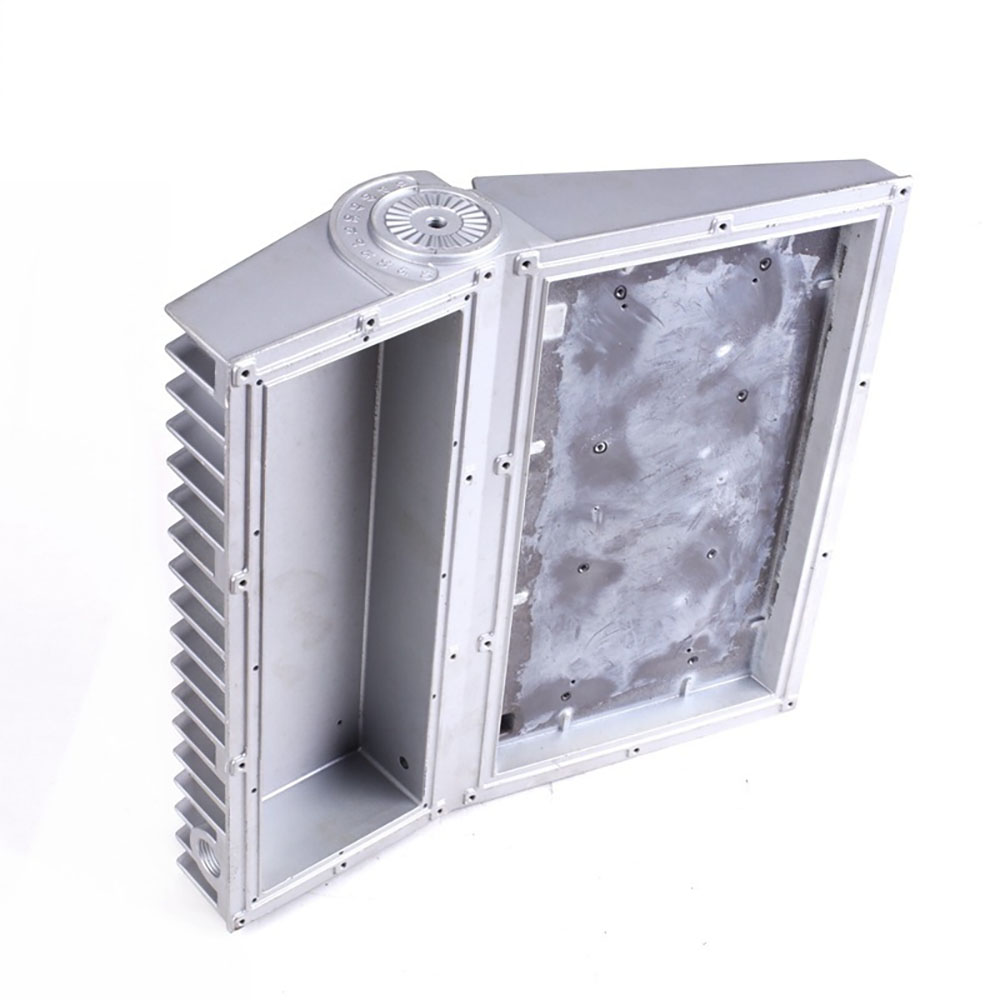

SCZY company adheres to the business philosophy of customer first, quality first, and development with integrity, specializing in the production of casting iron, casting aluminum, casting copper, Casting Steel, cating stainless steel and other CNC precision products. Customers only need to provide drawings or samples we will according them to manufacture customer requirements products.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.