Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

With the continuous development of the manufacturing industry, the requirements for the precision and materials of the parts are getting higher and higher, especially in the CNC Machining industry, in recent years, the requirements for CNC Precision Machining Parts have become higher and higher, and the shapes have become more and more complex. With the rapid development of aerospace, medical and marine engineering industries in recent years, the use of special alloy materials is also rapidly developing. Currently, the most commonly used special alloys are titanium alloys and molybdenum alloys. Due to the particularity of their materials, they are often used in a special environment. Especially titanium alloys, as everyone knows, the use of Titanium Precision Machining parts has developed very rapidly in recent years. Whether in aerospace, medical industry or in other industries, the use of titanium alloys is becoming more and more ordinary. Titanium alloy is famous for its low density, excellent strength, and strong corrosion resistance, but it is a big problem in CNC machining. Due to its high strength and high hardness, CNC machining is very difficult, which prompts us It is necessary to continuously improve processing equipment and improve the technical level of technical personnel. Therefore, many CNC machining manufacturers cannot produce this type of special alloy machining.

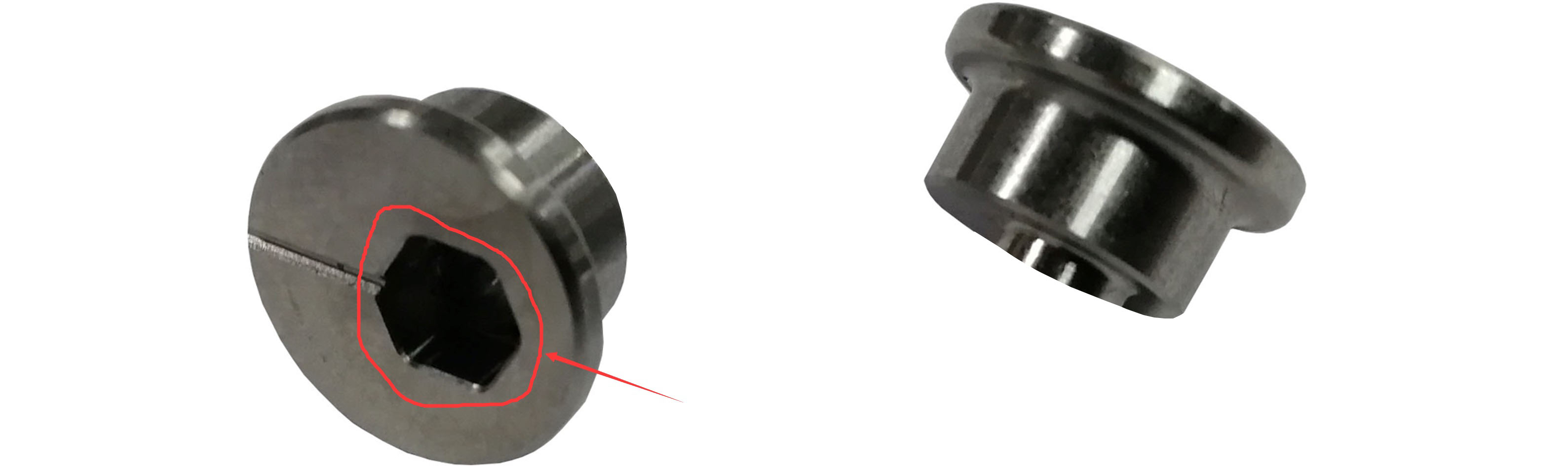

SCZY has very rich experience in CNC machining of special alloys such as titanium alloys and molybdenum alloys. We can provide better solutions according to the specific requirements of customers. For example, in the picture below we produce a Grade 5 titanium alloy inner hexagon product. Normally, the inner hexagon is formed by stamping with a punch die, so that the punching effect is good and the cost is low, but this is for larger batches. Because it takes a relatively long time to assemble the punch to the punch machine and then calibrate, if the number of subsequent punching is relatively large, this time can be ignored. But if the number is only a few dozen or more than one hundred, the cost is very high if the punch is also used for punching. The first batch of the product in the picture below is only 100 pcs. In addition to ensuring quality, cost is a key consideration for customers. Finally, after our continuous communication with our customers and let them fully understand the feasibility of the plan, they decisively agreed to our plan. Of course, we finally gave the customer a satisfactory answer. Not only did the product meet the customer's requirements, but also the cost was saved for the customer. Why not?

SCZY specializes in customizing all kinds of precision or high-precision Metal Machining and Plastic Machining Parts, especially with very rich experience in special alloy CNC machining. We can help customers analyze and solve potential problems.

If you need to know more, please send an email to: info@sczyltd.com Thank you.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.