Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

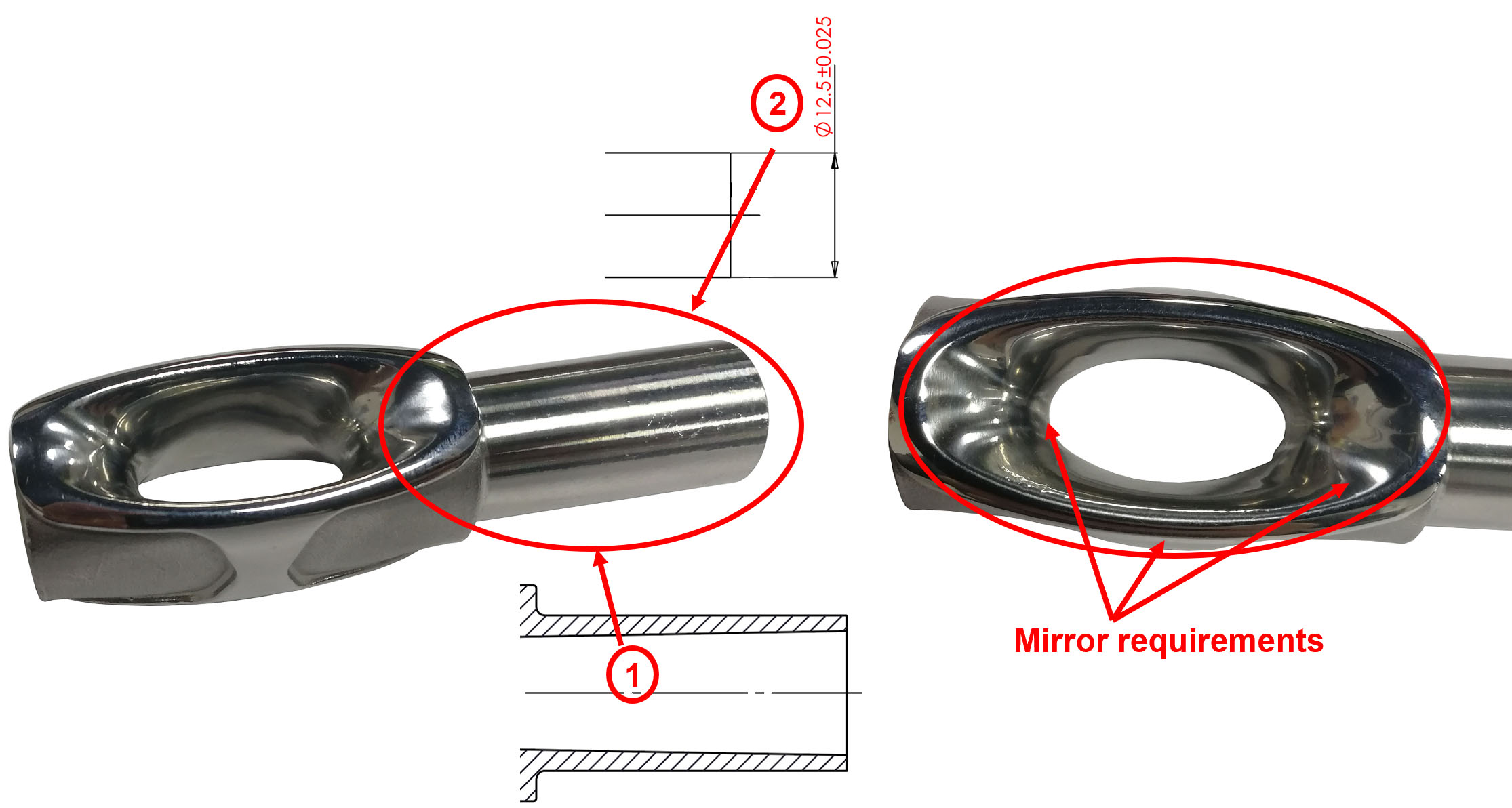

With the continuous development of the manufacturing industry, there are more and more requirements for product types, and the requirements for product quality are getting higher and higher. Investment Casting has developed very rapidly in recent years, but it also has higher and higher requirements for casting, such as precision requirements, appearance requirements, and so on. This allows us to continuously improve the technology and service to meet the requirements of customers and the ever-evolving industry. For example, the Stainless Steel Casting we produced in the picture below does not seem to be difficult, but if you know his requirements, you may be impressed.

What are the special requirements for this product? First of all, the blind holes at both ends of this product are very deep, with a depth of 40 mm. After the casting is completed, the sand inside is very difficult to clean. We finally solved it after continuous improvement of the process; secondly, the outer diameter of the product at both ends has assembly requirements, so we must Lathe is finished in order to meet the assembly requirements, but because the product is too long, it is easy to cause deformation when cast. At this time, it is difficult to ensure the coaxiality of the product at both ends, as well as the coaxiality of the inner and outer circles. Furthermore, the inner ring and outer ring of the middle part need to be mirrored. Due to the irregularity of the product, manual polishing is required. Moreover, the inner ring is relatively small and the polishing is quite difficult. As shown below:

For Investment Casting Parts, Stainless Steel Castings, Carbon Steel Castings, alloy steel castings, aluminum castings, Copper Castings, etc. are more commonly used in the manufacturing industry. So what kind of product is suitable for casting? First of all, the material must be metal, and for products with complex shapes, but not too high in terms of strength and accuracy requirements (of course, if only some assembly positions require high accuracy, we can achieve it through subsequent CNC Machining), and then The casting is suitable for large and small batch production, and the cost is low (compared to CNC machining, etc.).

Our SCZY provides not only investment casting, but also polishing and other treatments, as well as subsequent secondary CNC machining, or subsequent assembly services. We have many years and very rich experience in processing and service.

If you need to know more, please don`t hesitate to send an email to: info@sczyltd.com

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.