Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Investment Casting is a kind of casting process. Some people call it "Lost Wax Casting" or "Precision Casting". It can also be said to be a special casting improved from ordinary casting. Its precision and surface finish are higher than Ordinary casting is much higher. In some places where the precision requirements are not very high, Investment Castings can be used and assembled directly. Even in some positions that require precise assembly, we can meet the required requirements through local secondary CNC Machining of the product, which can reduce the product's cost. Below are some of the investment castings we have done.

SCZY committed to the production of stainless steel, carbon steel, alloy steel and copper and other Metal Casting parts, and also provides professional follow-up secondary CNC machining (for places with high precision requirements and direct casting cannot meet the requirements) and various surface treatments etc. Our Investment Casting Parts accuracy achieve CT4-6, surface finish Ra.1.6~3.2μm and the wall thickness can be reach 0.5mm. Our high-quality engineering team and quality inspection team ensure product excellent quality and in time delivery. We would be happy to provide a free quote for your upcoming project.

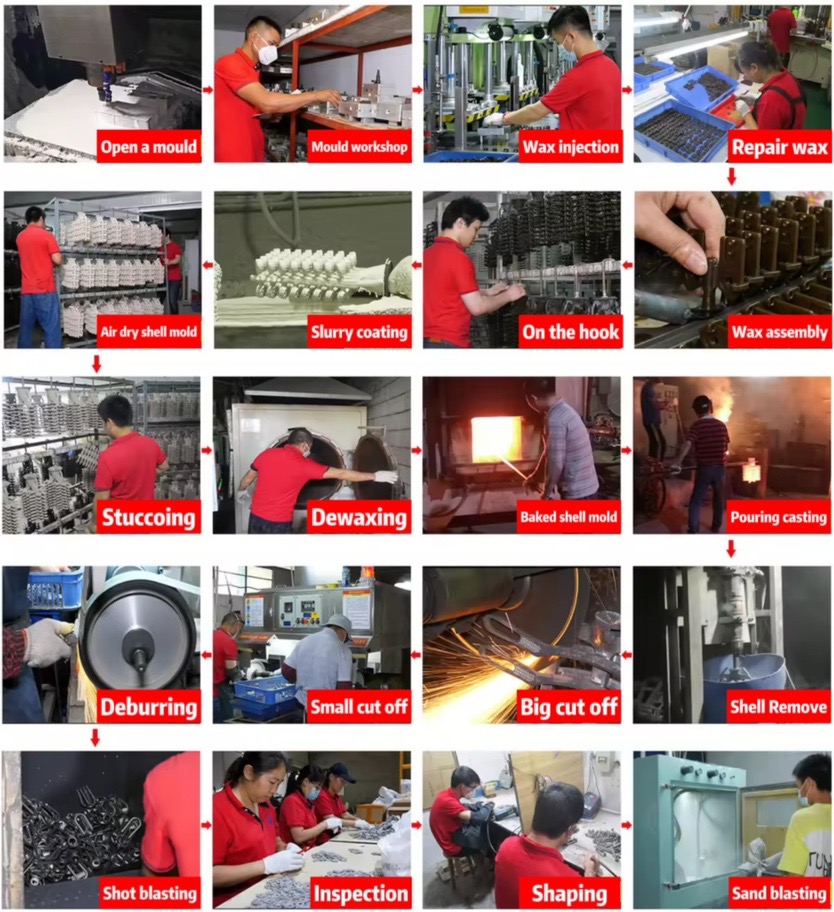

SCZY Precision Investment Casting Process

Our precision investment casting process is made through 48 processes, including product design, open a mold, wax injection, wax mold inspection, wax assembly, On the hook, cleaning wax mold, slurry coating ( it divided into fine slurry and coarse slurry, only one day do one step. it need repeat 7 times) to make a shell mold, air-dried and dewaxing in the slurry room, put the shell mold in a roasting furnace and burn it to about 1200℃,smelt the steel into molten steel, add auxiliary materials, and then pour the prepared molten steel into roasting In the good shell mold, a series of post-processing processes such as natural cooling, shell removal, shot blasting, large cutting, grinding, sand cleaning, acid soaking, sand blasting, quality inspection and repair, white washing, packaging, etc., until the qualified rough products is completed.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.