Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

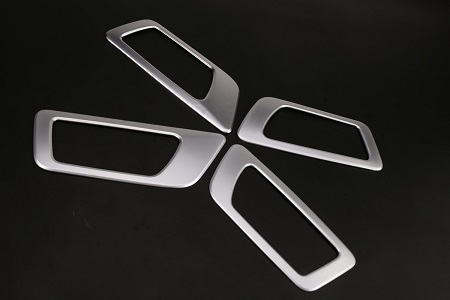

Stainless steel machinging technology refers to the process of cutting, folding, bending, welding and other mechanical processing of stainless steel to obtain stainless steel products required for industrial production based on the properties of stainless steel and Stainless Steel Machining equipment.We (Shenzhen SCZY Technology Co., Ltd) has specialized in this field about 15 years.Below will introduces the difficulties and Solutions of Stainless Steel Machining.

The difficulties in stainless steel machining

1. High cutting force and high cutting temperature

This type of material has high strength, large tangential stress and large plastic deformation during cutting, so the cutting force is large. In addition, the thermal conductivity of the material is extremely poor, causing the cutting temperature to rise, and the high temperature is often concentrated in the narrow and long area near the cutting edge of the tool, thereby accelerating the wear of the tool.

2. Serious work hardening

Austenitic stainless steel and some high-temperature alloy stainless steels are all austenitic structures, which have a large tendency to work hardening during cutting, which is usually several times that of ordinary carbon steel. The cutting tool cuts in the work hardening area, which shortens the tool life.

3. Easy to stick to the knife

Both austenitic stainless steel and martensitic stainless steel have the characteristics of strong and tough chips and high cutting temperature during processing. When the tough chips flow through the rake face, sticking phenomena such as bonding and fusion welding will occur, which will affect the surface roughness of the machined parts.

4. Tool wear is accelerated

The above materials generally contain high melting point elements, high plasticity, and high cutting temperature, which will accelerate tool wear, sharpen and change tools frequently, thereby affecting production efficiency and increasing tool use costs.

Mainly to reduce the cutting line speed and feed. Use special tools for processing stainless steel or high temperature alloys, and internal cooling is best for drilling and tapping

The solutions of stainless steel machining difficulties are as follows:

1. Use tools with high thermal conductivity.

2. Sharp cutting edge line: The chip flute insert is wider, which reduces the cutting pressure, so the resistance can be controlled.

3. Appropriate cutting conditions: Improper machining conditions will reduce tool life.

4. Choose the right tool: The stainless steel tool should have excellent toughness, and the strength of the cutting edge and the clamping strength of the coating film are also relatively high.

Product Range: CNC Machining , CNC Machining Parts , Precision Machining, CNC Milling , CNC Turning Parts , Machining, Forging, Forging Parts, Investment Casting, Die Casting, Casting Parts, Sheet Metal Fabrication, Product Assembly Service... Tel: +86-769-81582278 Mobile: +86 15889824829 (WhatsApp/WeChat) Email: sales@sczyltd.com Address: No. 1906, Vanke Center, Changqing South Road, Chang` An Town, Dong Guan City, Guangdong Province, PR China 523850

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.