Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

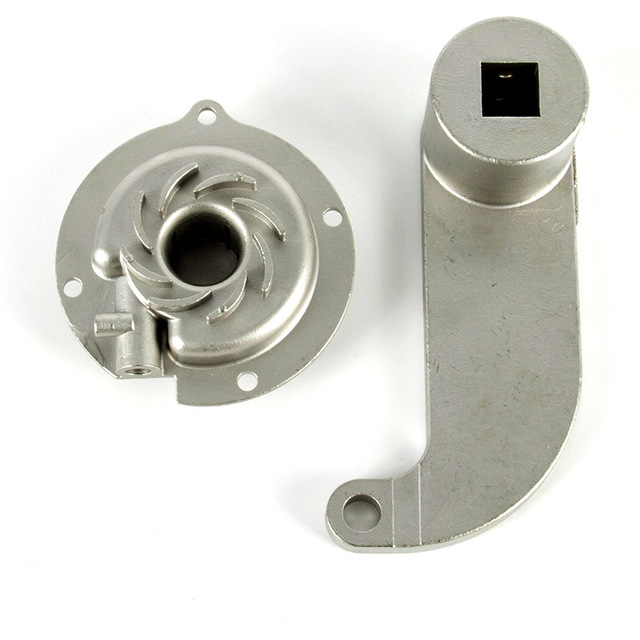

Now China's machinery manufacturing industry has made great progress, especially the development of Machinery Parts manufacturing industry. China is now the world's second largest economy and is gradually becoming the world's manufacturing center. Many European and American developed countries have shifted the production of mechanical parts to China. China has become an important base for European and American buyers to directly purchase globally. This brings opportunities to China's manufacturing industry. In addition to the economic crisis, many European companies have transferred some precision parts that were originally produced abroad to China for production in order to save costs. Therefore, for China's mechanical parts industry, it is really Spring. However, not all companies can enjoy this Spring. When many foreign companies enter China to find mechanical parts suppliers, they will still have a lot of requirements. It is still difficult to find factories with suitable prices and quality requirements among millions of suppliers in China. SCZY LTD is honored to be one of the leading manufactures among Chinese machinery parts manufacturers. We provide reasonable price and high quality products and can help clients ship the goods with one-stop service. We are sparing no effects to contributing to the Die Casting Products manufacturing as well as other Investment Casting Parts, Precision Machining Parts. Today we will talk about the application of Precision Die Casting products in the auto parts industry. Our products have been delivered all over the world for many automobile manufacturers as well as auto parts manufacturers, for example, the products are used in safety systems, fuel systems, transmission systems, electrical systems and decorative parts. And for example, as what we made the taper shaft for car dashboard...

Precision Casting products processing is the most commonly used production method in the automobile manufacturing process. Parts and components that account for about 10% of the total weight of the car are obtained by casting. For various parts with complex shapes that are difficult to form by other methods, as well as various parts that require wear resistance, pressure bearing, vibration damping, and low cost, part blanks can only be produced by casting process. Such as cylinder block, cylinder head, piston, piston ring, cylinder liner, intake and exhaust branch pipes, transmission case, steering gear housing, rear axle housing, brake drum, various brackets, etc. Generally, casted parts should be placed for a period of time to eliminate internal stress, which is called aging treatment. The main features of automotive castings are thin wall, complex shape, light weight, good reliability, high dimensional accuracy, and large scale of mass production. And can use a variety of materials, such as cast iron, cast steel, cast aluminum, cast copper, etc. Cast iron can also be divided into gray cast iron, ductile iron, vermicular graphite iron, malleable cast iron and alloy cast iron. With the continuous development of casting technology, the application scope of castings continues to expand. For example, crankshafts, connecting rods, gears and other parts made by forging technology in the past are gradually replaced by castings. For more information, you can feel free to discuss with us. Email: sandy@sczyltd.com

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.