Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Die Casting is Metal Die Casting on a die casting machine, and is currently the most productive casting process. Die-casting machines are divided into two categories: hot-chamber die-casting machines and cold-chamber die-casting machines.

In performance

1. The Hot Chamber Die Casting machine has high production efficiency, and the tonnage generally does not exceed 800 tons. It is usually used to produce small parts (for die-casting zinc alloy, magnesium alloy, etc.), and the actual production hammer injection speed is generally about 1m/s.

2.The Cold Chamber Die Casting machine has low production efficiency, and the upper limit of the tonnage range can reach more than 5,000 tons. It is usually used to produce large pieces (for aluminum alloys, magnesium alloys, and copper alloys). The actual production punch injection speed is generally about 2m/s.

In Structurally

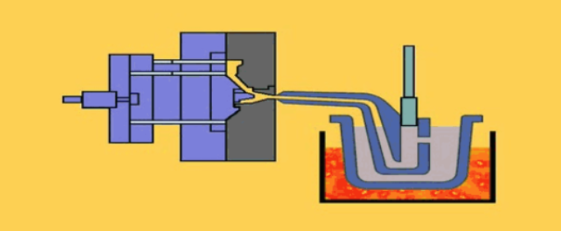

1. The pressing chamber and the crucible of the hot chamber die casting machine are connected together (the pressing chamber is placed in the crucible), and the hammer movement direction is perpendicular to the horizontal plane,and the injection mechanism generally has a certain slope with the horizontal plane (to facilitate the return of molten metal).As below picture

2. The pressure chamber and the crucible of the cold chamber die-casting machine are connected and separated, and the direction of movement of the punch is parallel to the horizontal plane.As below picture.

Advantage

1. The hot chamber die casting advantage is the production process is simple, the efficiency is high, the metal consumption is less, and the process is stable.

2. The cold chamber die casting advantage is good product quality, good surface finish, high strength and hardness, good interchangeability, can die-cast thin-walled and complex castings; high production efficiency.

Disadvantage

1. The hot chamber die casting disadvantage is the pressure chamber and the injection punch are immersed in liquid metal for a long time, which will affect the service life. And it is easy to increase the iron content of the alloy.

2.The cold chamber die casting disadvantage is the process is troublesome.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.